7 Gate Operator Parts to Check During Spring Cleaning

Mother Nature decided to change the weather for us in the Midwest in a hurry. Many states went from having over a foot of snow on the ground and frigid temperatures to highs in the sixties and large amounts of rain. Spring is right around the corner, and so is spring cleaning. This is a great time to get back out there and check over your gate operator to see what stress Mother Nature maybe have caused. Below is our list of different parts of your gate operator where you may see some wear:

- Chain wear – Does your chain need to be tightened back up, or maybe even replaced? It may also need to be lubricated.

2. Mice nests – Do you need to vacate the living or non-living animals that were looking for a warmer place to live during the winter?

3. Spider Webs – Do you need to clean the spider webs out of the operator? Believe it or not spider webs can cause issues. WARNING: ALWAYS remove power from operator before attempting to clean inside the operator.

4. Grease the bearing – Do the bearing on your rollers (that should have covers on them) need to be greased? There are operators that have bearings inside the operator box that need greased as well. Do any of the bearings need to be replaced?

5. Shafts and clutches – Are the shafts showing so much wear that the bearing is not making contact with them? Is the clutch still tight enough to operator the gate as it should?

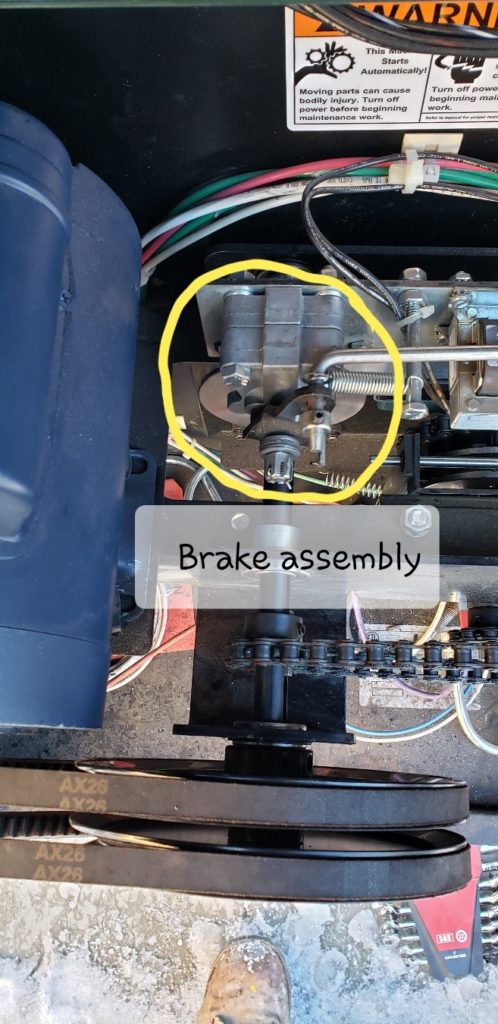

6. Brakes – Does your gate stop when the motor shuts off or does it coast?

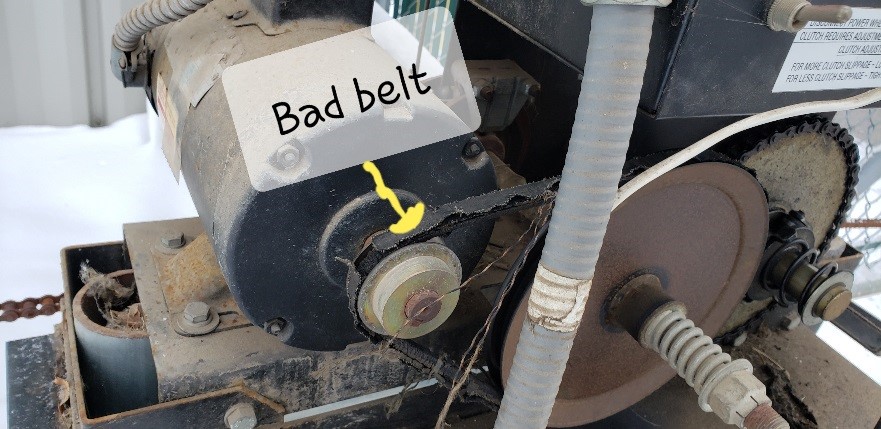

7. Belts – How does the tension on your belt look? How about the belt itself? What is the condition of the belt?

These are a few of the items that you can look at and/or have your professional installer inspect or replace for you. REMEMBER: Always shut the power off on the operator when sticking your hands in or around parts that may move. Contact American Access Company today to tune up your gate and ensure you have a safer summer.