Avoiding Accidents when Working with Other Contractors

Accidents do happen when different contractors are involved all on one project. As the projects reaches or even extends past the deadline, the pressure tends to lead to mistakes. You don’t want any accidents to occur because someone is trying to rush their job. Most accidents can be fixed or mended, but you likely can’t fix a lost lime or even a life. If you’re ever tempted to rush a job, remember that it will ultimately be easier to work safely and efficiently.

When accidents happen between two contractors’ scopes of work, they can typically be resolved with an easy solution or a repair or replacement of damaged items. For example: On a recent American Access Company project, after conduit had been laid out and concrete had been poured for walkways and driveways, it was time for us to install the gate access controls. After the access controls were installed, then it was time to install the safety devices, which can consist of photo eyes, safety edges, panic hardware, safety loops, or vehicle sensing devices.

Product Familiarity

Some of these devices are not common enough to be known by every contractor. This is not any different than if someone was explaining how to build a rocket ship. You may not know what the items do or even what they are for or how they are installed. When there is this uncertainty and lack of product knowledge, accidents happen.

Accidents Can Happen

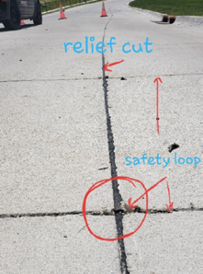

After we installed the the safety device, the safety loops are saw cut into the concrete in order to open the gate as a car drives over the loop. So, in this example you will see the concrete relief cuts being cleaned and filled after the loops were installed, sealed and in operation, which can cause an accident. The cost of this accident consisted of replacing 3 loops, fuses, and one control board. Luckily, no one was hurt.

This incident was caused because the loops were installed after the relief cuts were cut. Then the weather had turned cold, and the cuts were not filled in until the spring. Before we could fill the relief cuts, they needed to be cleaned out. Since the team used a saw to clean out the saw cuts, it also cut through the safety loops. Cutting through the safety loops caused the operators to work improperly, blew a few fuses and caused a control board to malfunction.

Keeping this example in mind, it would help to be mindful of another contractor’s work. If you are ever unsure of another contractor’s work, ask questions. We resolved this by removing of the existing loops and board, and then replacing the loops and board.